Categories

Categories

Brands

Brands

Hardness Testing Defined

Posted by on

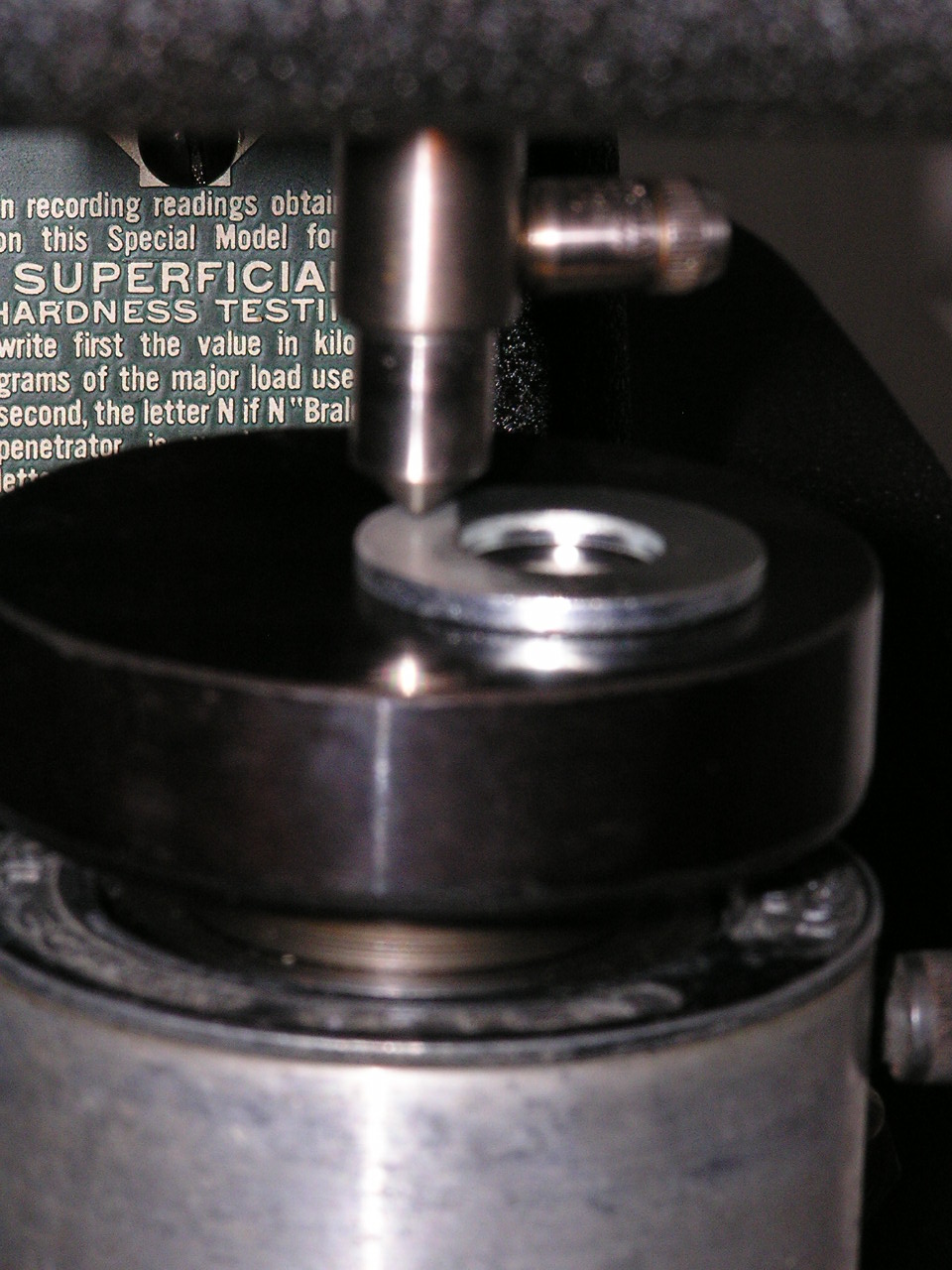

The resistance to permanent indentation is how hardness of metal is typically defined. A hardness test is that of a hard indenter pushing into a sample surface under a specific load for a set amount of time. A measurement is made of the size or depth of the indention. What is the main purpose of the hardness test? To determine if the material is suitable for the purpose for which it is to be used. This type of testing is quite easy to perform and has become the most common material inspection method for metals and alloys.

Material has many different fundamental properties but hardness is not one of them. Hardness values were determined by a chosen method of a set load by a conceived point geometry on a material for a set amount of time. The National Institute of Standards and Technology NIST has the objective to standardize hardness measurements and has the responsibility for traceability in hardness measurements. The hardness test procedure standard was developed by the American Society for Testing and Materials ASTM and the International Organization for Standardization ISO.

Before the development of the hardness tester, hardness was determined by a variety of methods. One of the earliest was a comparison of material hardness using the scratch method. This is done by taking a scratch tool of desired hardness and attempting to scratch a sample materials surface with it. If it scratches the surface, the tool is harder than the sample material. If the tool does not scratch the sample material then the sample is harder than the tool.

By Jeff Briley Owner, Brystar Tools

Loading... Please wait...

Loading... Please wait...