Categories

Categories

Brands

Brands

Casehardened Steel

Posted by on

Testing the hardness of case hardened steel provides important information about the hardness and depth of the case. The "case" is the harder outside layer and the inner part is called the "core". When testing hardened material it is very important that the depth of case is adequate to support the indenter properly. The case depth should be at least 10 times the depth of the indentation. For instance, if the hardness of the case is HRC62 and the depth of the indentation is .003", the case depth must be at least .030". This is necessary to obtain an accurate reading. Let's say a HRC test is made and the result is less than HRC62. This may mean that the case hardness is too soft or that the case depth is less than .030". If you were using a superficial Rockwell hardness tester on the HR15N scale the minimum case depth would need to be .015".

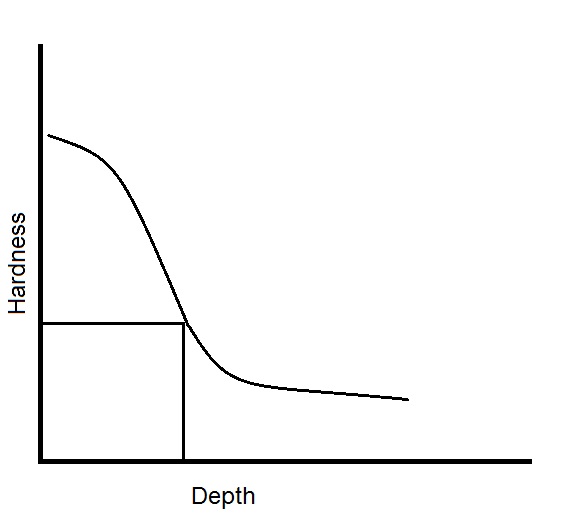

It would be important to know what the case depth actually is by using a microhardness tester. Case depth can be recorded as either "effective case depth" or "total case depth". Effective case depth is a depth at which a minimum specified hardness value is achieved. Total case depth is the depth at which hardness becomes equal to the core hardness. There are several methods used to determine this. One of the most common is the cross section hardness traverse method using a microhardness tester and graphing the results. Microhardness tests are more time consuming than Rockwell tests so once the case depth is determined then production runs could be monitored with a regular or superficial Rockwell tester, depending on the case depth.

By Jeff Briley

Owner, Brystar Tools

Loading... Please wait...

Loading... Please wait...